What Is A Rolling Mill Used For

Many metal working plants employ the use of rolling mills. Whether your business needs a new or used piece of equipment, our team at American Steel Products can help you find the right equipment to solve your needs.

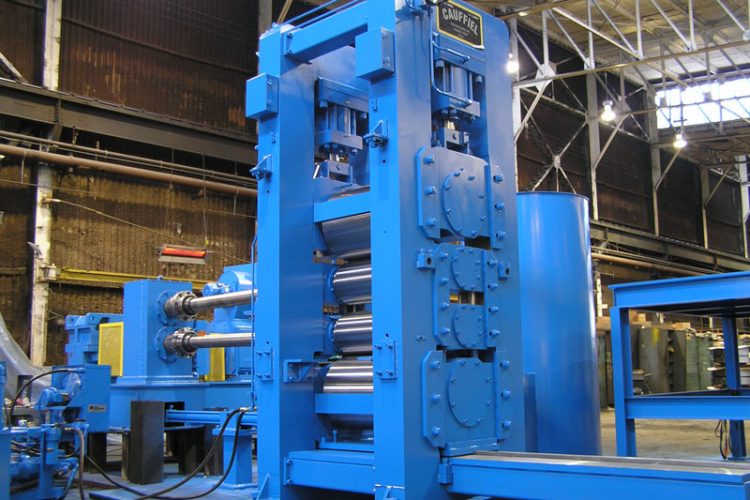

Simply put, rolling mills are used to decrease width and increase hardness of the metal. Though there is more to a rolling mill than this simple definition.

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling.

In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock, and so on), bar stock, and rails.

There are major differences between hot rolling and cold rolling. Hot rolling is more pliable and the surface is not shiny. Cold rolling is worked under high intensity and offers a harder finished product that has a shiny surface.

There are many types of rolling processes, including ring rolling, roll bending, roll forming, profile rolling, and controlled rolling.

We typically have a few select pieces of machinery available for purchase or we can search the marketplace for the piece of equipment that best suits your needs. Our team is ready to help you with the right solution for your business.

With over 60 years of experience and a real focus on customer satisfaction, you can rely on us for your next project.

We provide professional renovation and installation services with a real focus on customer satisfaction. We have proven results for setting exceptional standards in cost control, planning, scheduling and project safety and the experience that gives us a competitive advantage over others in our field.