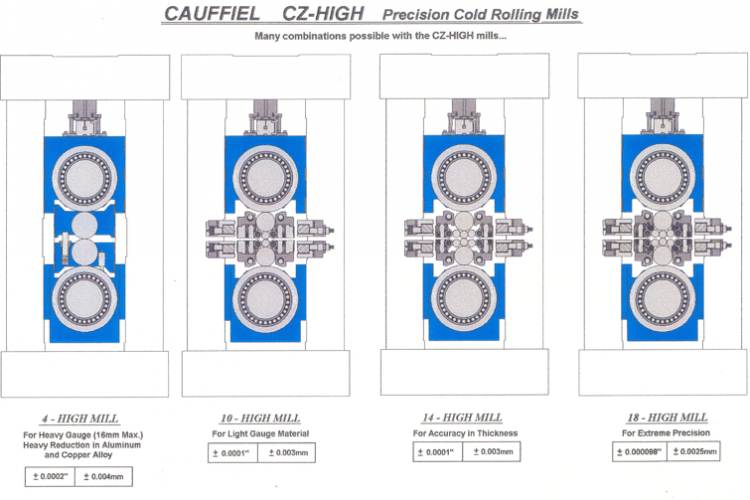

Cluster Mills

Cluster mills can be 10-high, 14-high, or 18-high. In all cases, cluster mills are designed to reduce stainless or high carbon, high strength alloy steels, or any material when reducing increases the yield strength. Cluster mills have the advantage of running very light gauges under precision tolerances.