A pipe straightener which utilizes parabolic upper and lower rollers combined with hydraulic cylinders to apply pressure between alternate parabolic rollers so as the pipe is moved between the rollers the bends and twists are removed. By adjusting the top and bottom rollers from a right angle with respect to the pipe up to approximately 45 DEG with the upper rollers being adjusted in opposite angular relation to the lower rollers, pipe may be readily straightened. At least some of the upper rollers and some of the lower rollers are power driven, preferably with hydraulic motors, the conduits of which hydraulic motors are connected in series so that all the rollers will be driven at a uniform speed, with certain rollers being idler rollers. The entire device may be mounted on a structural frame, which in turn is mounted on a trailer axle and may be trailed from place to place, which obviates the necessity of bringing the bent or “cork screwed” pipe to the machine. A V-trough is provided, at one end of the machine, to guide the pipe to and between the rollers and a cone shaped guide is provided at the opposite end for guiding the pipe outward therefrom. The source of hydraulic power is usually furnished by the vehicle towing device, however, a separate and independent hydraulic system, having an outside source of power, may be used, such as a motor or internal combustion engine. Both the upper and lower parabolic rollers are adjustable to vary the center distances between the rollers to enable the device to be used on pipe of all sizes.

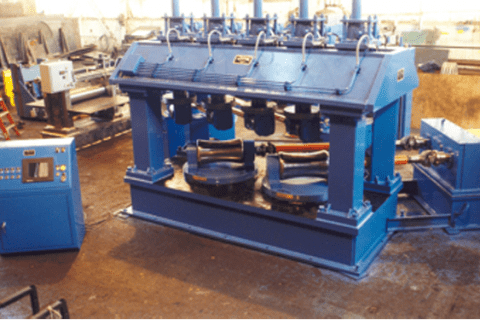

A cross axis pipe straightener from ASP a multi-roll machine for straightening pipe without subjecting it to excessive cold work or introducing sufficient ovality as to affect the physical properties, specifically the collapse strength. The seamless or as welded pipe is straightened cold, largely by passing it through a straightener including spaced pairs of 5 or 7 or more rolls where each bending moment can correct curvature in the length of pipe. One pass is sufficient to attain ASTM straightness and ovality tolerances. The cross rolls, one concave and the other convex, rotate the pipe on its axis by friction and feed it axially. Each opposing pair of driven rolls (one upper and one lower) can be moved via hydraulics, together in tandem or individually up or down to achieve the desire bending moment to make the pipe straight. This action will counter-act forming, internal material, or welding heat stresses. Too much straightening can damage the OD characteristics of a tube, pipe, or wire, so you must always monitor for side effects that prevent you from achieving the highest level of quality within a process. All parabolically shaped rolls are forged, hardened and ground D2 alloy for long life.

Our current equipment includes:

3” Sutton #1-1/2B, 5-Roll Rotary Type

3” Sutton #1-1/2B, 5-Roll Rotary Type

6-5/8” to 1” Sutton, 5-Roll Rotary Type

6-5/8” to 1” Sutton, 5-Roll Rotary Type